SuperMax

Designed for Strength & Longevity

SuperMax was specifically designed to be used in an environment of high ultraviolet exposure. Ultraviolet light will degrade exposed plastic extremely fast.

Hurricane Shutters are tested before any exposure to ultraviolet light. If a screen hurricane shutter is not designed specifically to operate in an ultraviolet environment it can become useless for storm protection.

Hurricane screens have two crucial components that can be affected by ultraviolet light. The screen and the method of connection of the screen to the end retention. If the strength of either of these components is diminished the shutter as hurricane protection becomes useless.

Hurricane Shutters are tested before any exposure to ultraviolet light. If a screen hurricane shutter is not designed specifically to operate in an ultraviolet environment it can become useless for storm protection.

Hurricane screens have two crucial components that can be affected by ultraviolet light. The screen and the method of connection of the screen to the end retention. If the strength of either of these components is diminished the shutter as hurricane protection becomes useless.

Thread

There are two methods of connecting the screen to the end retention. 1) sewing the screen to the end retention 2) thermally welding the screen to the end retention. Custom Hurricane Products is the only company using the welding process.

Polyester Thread is predominately used in the hurricane screen industry. It is cheap and has good strength and is simple use in industrial sewing machines. Polyester thread deteriorates rapidly when exposed to Ultraviolet light.

There are Polyester threads with UV inhibitors that only will extend the threads strength by 20%. This is not sufficient in a ultraviolet environment if using it as a connection method for a hurricane shutter.Looking at the chart you can see that Polyester thread loses 62% of the strength the first year, 78% the second year, and 85% the third year. Polyester with inhibitors strength will lose 50% the first year, 63% the second year and 68% the third year.

Unfortunately, a visible inspection cannot determine the extent of degradation. Custom Hurricane Products is the only manufacturer that uses PTFE thread on its products. Why don’t other companies use it? Cost! Polyester thread costs $8.00 a pound and PTFE thread costs $166.00 a pound.

Florida Building code tests the products before any ultraviolet exposure.

Screen

There are two screens predominately used for see-through hurricane screen shutters. Polypropylene and OmegaTex.

Polypropylene is used predominately in the hurricane industry. Very inexpensive. It should only be used during hurricane events because of its extreme degradation when exposed to ultraviolet light. It cannot be coated due to the molecular single chain composition. Nothing sticks to it. It degrades faster than polyester when exposed to ultraviolet light. Final telltale signs of degradation are shrinking, fading, ripping and then it literally turns into powder

Florida Building code tests the products before any ultraviolet exposure.

OmegaTex screen utilizes polyester fibers and Aramid fibers. A well-known Aramid fiber is Kevlar©. The fibers are thickly coated with an ultraviolet blocking coating to stop 100% of the penetration of ultraviolet light. It is the only fabric specifically designed for the hurricane industry. It is the only fabric that has a warranty against the effects of degradation from ultraviolet exposure. Cost of OmegaTex is 6x more than polypropylene

Polypropylene is used predominately in the hurricane industry. Very inexpensive. It should only be used during hurricane events because of its extreme degradation when exposed to ultraviolet light. It cannot be coated due to the molecular single chain composition. Nothing sticks to it. It degrades faster than polyester when exposed to ultraviolet light. Final telltale signs of degradation are shrinking, fading, ripping and then it literally turns into powder

Florida Building code tests the products before any ultraviolet exposure.

OmegaTex screen utilizes polyester fibers and Aramid fibers. A well-known Aramid fiber is Kevlar©. The fibers are thickly coated with an ultraviolet blocking coating to stop 100% of the penetration of ultraviolet light. It is the only fabric specifically designed for the hurricane industry. It is the only fabric that has a warranty against the effects of degradation from ultraviolet exposure. Cost of OmegaTex is 6x more than polypropylene

End-Retension Systems

- There are four basic types of end retention systems for retractable hurricane screen shutters. Rope, Luft, Zipper, and FlatLay. The Luft and zipper system use two separate components connected by polyester thread. The rope system is integrated to the screen with thread. All three of these systems structural integrity relies on the strength and durability of the sewing thread.

When these 3 end-retention systems travel up and down in the side rails and friction occurs directly to the screen. Each cycle of going up and down eventually will affect the integrity of the screen due to the motion and physical contact.

There are four basic types of end retention systems for retractable hurricane screen shutters. Rope, Luft, Zipper, and FlatLay. The Luft and zipper system use two separate components connected by polyester thread. The rope system is integrated to the screen with thread. All three of these systems structural integrity relies on the strength and durability of the sewing thread.

When these 3 end-retention systems travel up and down in the side rails and friction occurs directly to the screen. Each cycle of going up and down eventually will affect the integrity of the screen due to the motion and physical contact.

When these 3 end-retention systems travel up and down in the side rails and friction occurs directly to the screen. Each cycle of going up and down eventually will affect the integrity of the screen due to the motion and physical contact.

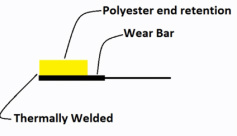

SuperMax’s FlatLay end re-tension does not use sewing thread. A wear bar is welded directly to the surface of the screen’s top and bottom to isolate the screen from the effects of friction from the rail. Even though this increases production time by 3x SuperMax’s screen integrity will last well beyond the 10-yr. limited warranty. A one inch wide webbing strip is the welded to the face of the wear bar. Welding allows the entire surface to be connected instead of relying on just individual stitches. This connection along with incredible strength of the screen is the reason SuperMax can achieve impacts absorbing 3x the required amount from Florida Building Code and Miami / Dade NOA. No other hurricane screen has matched SuperMax tested impact level E rating.

The SuperMax Solution

SuperMax Hurricane Screen end retention is thermally welded to the screen eliminating sewing thread.

The screen fibers are coated with ultraviolet blocking plastic.The coating is exposed, not the fibers.

The edge retention is mounted to only one side eliminating the wedge effect.

A wear bar isolates the screen from the rail eliminating friction and wear to the screen.

The fasteners are centered to the rail eliminating the lever effect placing less stress on the structure.

The screen fibers are coated with ultraviolet blocking plastic.The coating is exposed, not the fibers.

The edge retention is mounted to only one side eliminating the wedge effect.

A wear bar isolates the screen from the rail eliminating friction and wear to the screen.

The fasteners are centered to the rail eliminating the lever effect placing less stress on the structure.